Select your site:

International

The Duralloy™ Pearlescent range is a collection of popular pearlescent and metallic finishes, delivered with warranty grade advanced durable polyester thermosetting powder.

Duralloy™ Pearlescent is suitable for the following applications:

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|

| Interior | · | · | · | · | · | · | · |

| Exterior | · | · |

| Interior | Exterior | |

|---|---|---|

|

· | · |

|

· | · |

|

· | |

|

· | |

|

· | |

|

· | |

|

· |

Duralloy is only suitable for coastal environments >100m from the high tide line and are NOT suitable in strongly acidic environments so the pH must be between 5 and 9.

Please refer to the ‘Interior and exterior environments close to liquids other than the sea’ section for warranty implications for such environments.

*Warranties are only valid when applied by a DGL Accredited Powder Coater to the warranty specification on recommended projects, and subject to specified warranty terms and conditions.

Developed primarily for use on extruded aluminium, including window and door joinery, and extruded aluminium panel work on class 1 & 10 residential buildings under the Australian Building Code. Duralloy is also suitable for use over a variety of substrates, including mild steel and aluminium.

Ideal for warranty grade application over:

Duralloy can also be used on the following but is not warranted:

Durable polyester thermosetting powder

Duralloy

Pearlescent look

Matt and satin finishes

Interior and exterior use

See how this product rates on selected measures below.

The pre-treatment process must be capable of meeting the performance outputs as described in AS3715 and AAMA-2603

Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained.

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated.

If your site uses a dry off oven to assist in the pre-treatment process, consult your pre-treatment supplier for advice, but generally;

Steel substrates shall be prepared as follows:

Electrostatic Spray

Metal Temperature:

210° : 4 mins minimum

200° : 5 mins minimum

180° : 8 mins minimum

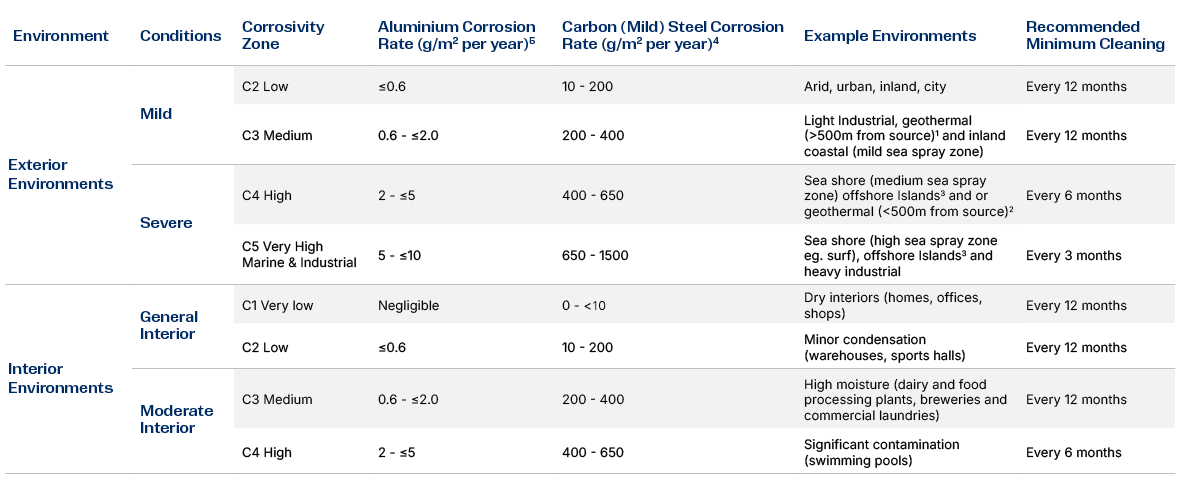

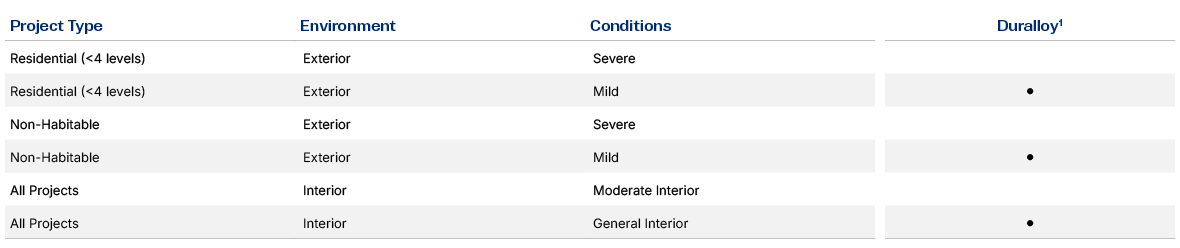

Use the tables below to determine the appropriate the product choice you have to gain a Alumi Shield™ warranty by determining the environment that your project will be exposed to.

Duralloy™ Pearlescent can also be used on the following metals, but these do not have a product guarantee. Steel (mild), bright/semi bright steel, black steel and blue steel. Galvanised steel, stainless steel and Zincalume®. Use the tables below to determine the appropriate the product choice you have to gain a Steel Shield™ warranty by determining the environment that your project will be exposed to.

All DGL powder products are NOT suitable in strongly acidic or caustic environments so the pH must be between 5 and 9.

1. Duralloy is only suitable for coastal environments >100m from the high tide line.

* In Mild (Medium) exterior environments and Moderate (Medium) interior environments, a 10 year corrosion warranty is available with a Zincshield, Grey Primer/E-Prime and the indicated top coat system. Without Grey Primer/E-Prime a 5 Year corrosion warranty is available.

Please refer to ‘Interior and exterior environments close to liquids other than coastal, river and lake salt water environments’ for warranty implications where powder coatings may be in close proximity to liquids.

Use the following table which references AS 2312.1, SNZ TS 3404 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories.

1. Geothermal environments greater than 500m of a bore, mud pool, steam vent, or other source with a pH between 5 and 9. For pH outside this consult DGL.

2. Geothermal hot spots within 500m of a bore, mud pool, steam vent, or other source.

3. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium and Carbon (Mild) Steel are determined by the following standards:

4. The corrosion rates for the first year of exposure for the different corrosivity categories of Aluminium are determined by the following standard:

1. Please note chemically treated water includes antimicrobial treatments, e.g. in pools, anti-corrosive chemicals, and soapy water in bathrooms and showers.

■ Where indicated Alumi Shield™ warranties are available on areas >than 1m from the liquid.

✓ Where indicated Alumi Shield™ warranties are available on areas >than 2m from the liquid (ie outside the splash zone).

● Where indicated Alumi Shield™ warranties are available any distance from the liquid.

Alumi Shield™ warranties are only available when applied by a DGL Accredited Powder Coater to the warranty specification on recommended project types and conditions.

All DGL powder product are NOT suitable in strongly acidic or caustic environments so the pH must be between 5 and 9.

Alumi Shield™ warranties are not available if the powder coating is immersed in any liquid.

On pre-treated architectural aluminium when applied by a DGL Accredited Powder Coater to the warranty specification on recommended project types and conditions.

For more information on our DGL Alumi Shield™ warranty program click here.

Environments must be:

Please note chemically treated water includes antimicrobial treatments, e.g. in pools, anti-corrosive chemicals, and soapy water in bathrooms and showers.

Only DGL Accredited Powder Coaters are able to issue our DGL Alumi Shield™ warranties after demonstrating their capability to meet stringent quality conditions and international standards.

For more information click here.