Select your site:

International

Perforated aluminium is sheet aluminium that has been manually or mechanically stamped, punched or cut to create a pattern of holes, slots, or decorative shapes. The sheets are typically used on architectural residential and commercial developments and can provide acoustic dampening performance and

energy savings through reductions in lighting and heating costs.

Expanded aluminium is a type of sheet metal which has been cut and stretched to form a regular pattern (often diamond-shaped) in a mesh-like form. In contemporary architecture, expanded aluminium has been used as an exposed facade or screen material which can be formed into simple or complex decorative shapes.

Filiform corrosion can develop where a coating is too thin, particularly around sharp edges that are common in perforated and expanded aluminium designs, leading first to cosmetic imperfections and ultimately to film failure and corrosion.

To prevent filiform corrosion it is essential that the sharp edges on the perforated and expanded aluminium are protected with a sufficient film build, particularly in environments where condition have a high corrosivity. As a result in high corrosive environments DGL recommends an additional coat with E-Prime, an epoxy modified powder primer, below recommended top coats.

DGL recommend an Alumi Shield™ Warranty system for both interior and exterior usage on perforated and expanded aluminium. The use of a E-prime powder primer is mandatory in conditions of high corrosivity below a recommended top coat. Although not mandatory, the use of E-prime is also recommended in all other environments to ensure a sufficient film build is achieved. Where E-prime is not used (as it is not mandatory) it is essential that the top coat film build be sufficient to meet minimum film build requirements and protect around sharp edges.

All DGL Alumi Shield™ Warranties are available when applied by a DGL Accredited Powder Coater to a approved specification.

Use the following table to help identify the product and system choice you have for the perforated or expanded aluminium on your project. Refer to the conditions information to determine the environment that your project will be exposed to.

For more information on DGL Alumi Shield™ warranties visit here

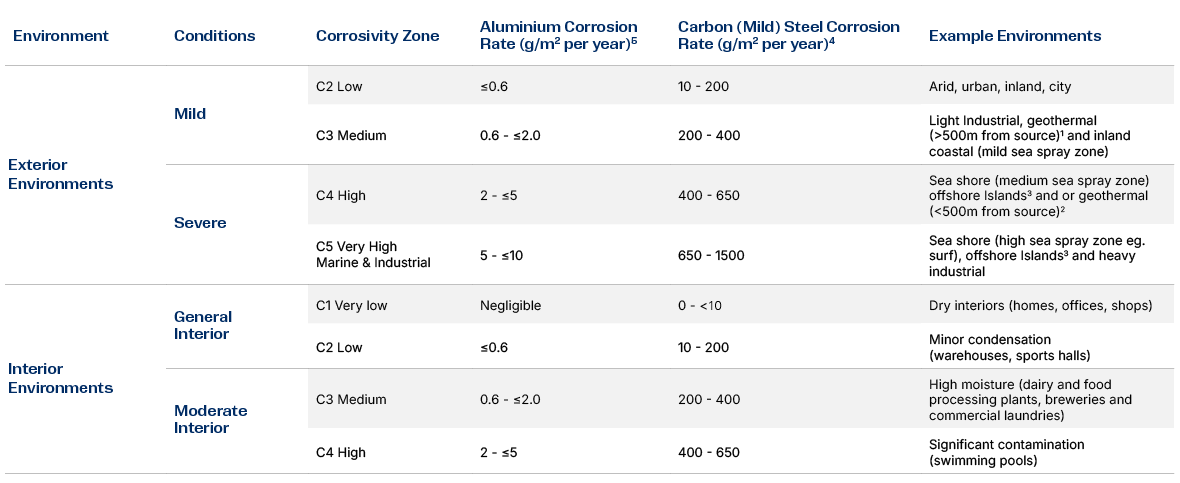

Use the following table which references AS4312 and ISO12944 Atmospheric corrosivity zones in Australia to define the environmental conditions and product is suitable for.

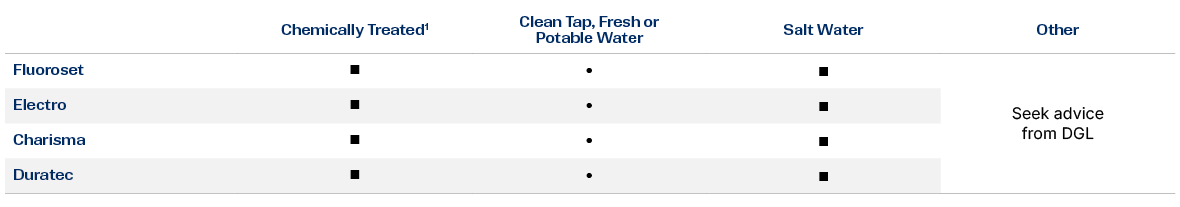

For powder coated assets close to liquids other than the sea, eg fences near outdoor swimming pools, fountains, outdoor bathrooms or furniture etc please refer to the guidance below for your product options for your project.

For more information on DGL Alumi Shield™ warranties visit here

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project.

To send an enquiry to our Advice Line, please visit the Contact Us page.